The Role of Technology in Industrial Safety

Every workplace must have a safety program as an integral part of its business operation. The main goal of a safety and health program is to prevent workplace injuries, illnesses, and deaths and the financial suffering these events can cause for workers, their families, and employers.

Safety Program Benefits

Safety and health programs help businesses prevent workplace injuries and illnesses, improve compliance with safety regulations, reduce costs, including vast reductions in workers’ compensation premiums, engage workers, enhance an organization’s ethics and morals, and increase productivity. A workplace without injuries is a productive workplace.

Safety Program Elements and Examples

The Occupational Safety and Health Administration (OSHA) recommends including seven main elements for an effective safety and health program. These elements include management leadership, worker participation, hazard identification and assessment, hazard prevention and control, education and training, program evaluation and improvement, and communication and coordination for host employers, contractors, and staffing agencies.

Some examples of management leadership include supervisor safety observations, daily toolbox talks, and conducting pre-job briefs. Worker participation examples include safety committee engagement, reporting near misses and incidents, and participating in creating and improving risk assessments. Examples of hazard identification, assessment, prevention, and control include performing risk assessments and issuing permits for tasks like Hot Work or Live Electrical Work. Education and training include new hire orientation, general safety training such as Hazard Communication, and on-the-job training specific to the task to be performed. On at least an annual basis, the safety program should be evaluated to ensure it is effective in preventing accidents, injuries, and illnesses.

Traditionally, these elements are managed by Microsoft Office programs such as Word & Excel. However, recently, Environmental, Health, and Safety (EHS) Software is becoming more popular with managing and tracking information to digitize and streamline EHS processes. But what if you had an EHS software that not only stored data on the EHS program but also automatically captured data for the facility?

Enhancing Your Safety Program with Artificial Intelligence (AI)

Any organization’s safety program will immediately be upgraded with a digital solution and automatic data analytics powered by AI. Be Global Safety’s (BGS) software can manage safety program elements and has the ability for real-time detection of near misses. Reporting a near miss is a crucial element of a site’s safety program, and its importance should be emphasized. Reporting near misses improves the safety program to catch unsafe conditions, acts, or procedures before an injury, fire, or property damage occurs. With real-time detection of near-miss reporting, BGS software can alert supervisors or EHS personnel of the potential near miss and store the video in the software for analysis.

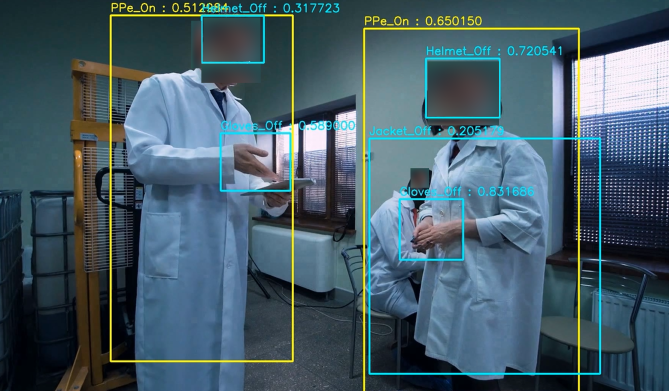

Employees should be reporting near misses, but what if that employee was extremely busy or forgot to report it? An unreported near miss is an incident waiting to happen. But with BGS, the near-miss is automatically captured in the system, sends a notification of a near miss, and is ready for evaluation for continuous improvement of the facility’s safety program. The automatic detection of near misses is only one example of how BGS can improve a site’s safety program. In addition, it has the ability of Personal Protective Equipment (PPE) detection, spill and fire recognition with emergency notification, and can even identify ergonomic concerns such as improper lifting techniques.

Author: Brandy Bossle, CSP, ASP, CSD

Brandy Bossle is Triangle Safety Consulting LLC’s Owner and Principal Consultant.

Brandy has extensive experience in Occupational Safety and Health.

Her roles have included:

- Industrial Hygiene Consultant.

- Environmental, Health, and Safety Specialist in the private sector for a large manufacturing facility of over 700 employees.

- Corporate Environmental and Safety Manager for a leading manufacturer and supplier of electrical components with over 14,000 employees.

Pingback: Be Global Safety selected in TechStars Industry of the Future Accelerator - Be Global Safety

Pingback: Digitalizing Safety Incident Reports in Manufacturing with AI - Be Global Safety